SYSTEMS/GLASS AND METAL CURTAIN WALLS

Structural Neoprene Gaskets

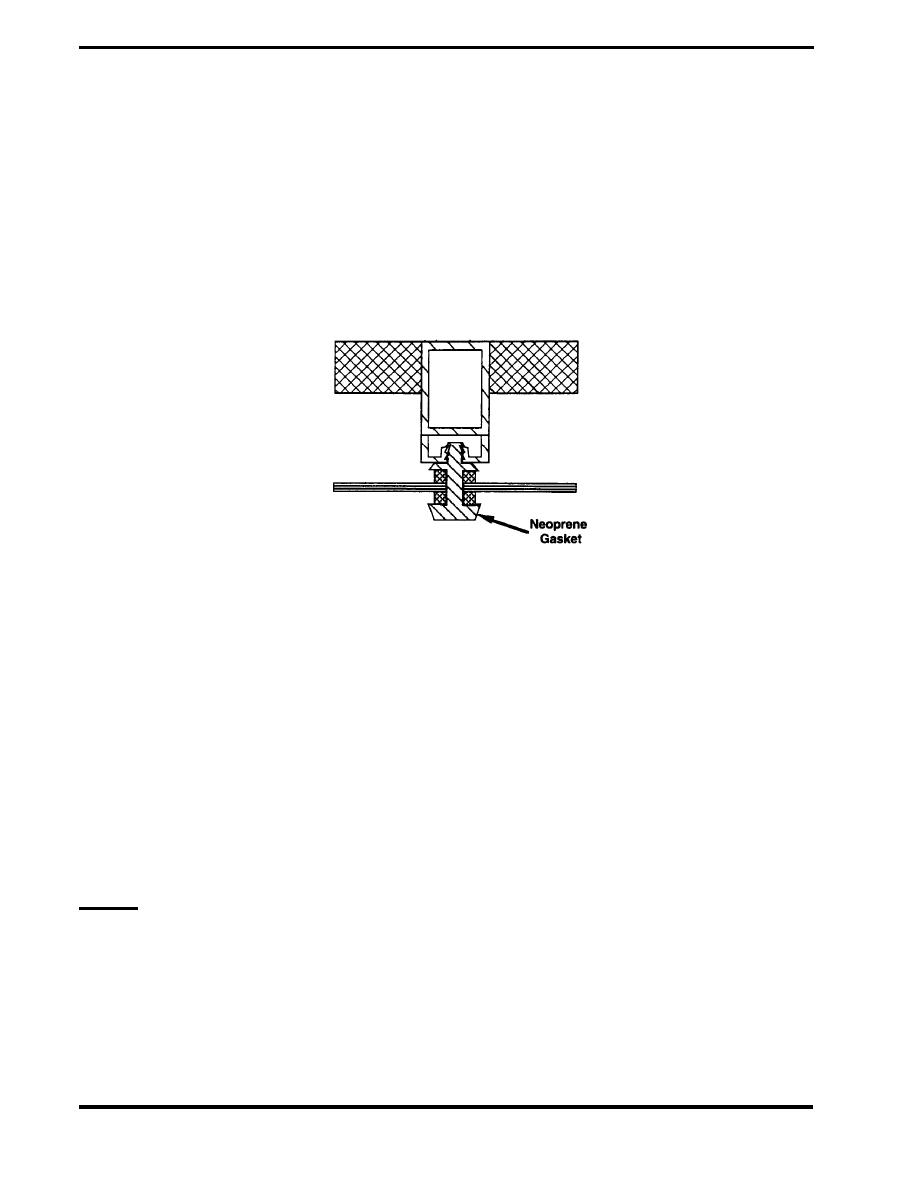

In structural, or zipper, gaskets, an extruded neoprene gasket that incorporates glazing pockets is

attached to a metal support system. This system, shown in Figure 4.1.7, is simple and the thermal

performance is generally excellent. In specifying this type of system, one must consider its visual

appearance, the structural support system, the size of the gaskets and the anticipated building

movements. It is usually used in small to medium scale buildings of limited height to create strip

systems or vertical ribbon systems. Maintenance of this system is critical as the neoprene is

exposed to the elements; concerns have been expressed about the life expectancy of the

neoprene.

ACCEPTABLE

Figure 4.1.7 Structural Neoprene Gasketed Mullion

Interfaces with Other Envelope Systems

Intersections between curtain wall systems and other envelope systems are key locations where air

barrier and insulation system continuity must be maintained. Quirouette and Brand have identified

several such interfaces and have described appropriate designs where continuity is maintained by a

structurally adequate air barrier that is secured between the curtain wall and the appropriate

element in the other component. A rigid air barrier material is suggested for this application so that

insulation can be brought into intimate contact with its surface. All of these designs are for heating

climates, therefore the insulation is located on the outside of the air barrier. In all of these details,

the air barrier is also sewing as the vapor retarder.

Parapet

Figures 4.1.8 and 4.1.9 contain two presentations of a parapet with a metal curtain wall exterior.

When the curtain wall system is brought up the outside of the parapet, it is exposed to colder

temperatures, leading to potential condensation problems from the exfiltration of moist interior air.

The exposure of the parapet to extreme temperature cycling can lead to structural concerns as well.

PAGE 4.1-6

Previous Page

Previous Page