SYSTEMS/GLASS AND METAL CURTAIN WALLS

Most guidance on mullion design contained here and elsewhere concerns straightforward horizontal

sections and plans sections, and does not generally address more complex configurations. These

include intersections of horizontal and vertical mullions, doglegs and other transitions. The lack of

adequate design details for these complexities are a common source of performance problems due

to the unusual stresses and movements that occur at these locations. An adequate design must

include details for all mullions, intersections between mullions and locations where curtains walls

meet other envelope systems. Without the provision of design details for all locations, the

installation at these irregularities is left to the mechanic in the field.

A variety of alternate mullion designs have been developed to provide a thermal break while

meeting the structural performance requirements of these elements. Five alternative designs are

presented below: Structural or Stopless Glazing, Poured-in Place, Screw-on-Face with Snap-On

Cover, Internal Slide-In Spacer, and Structural Neoprene Gaskets

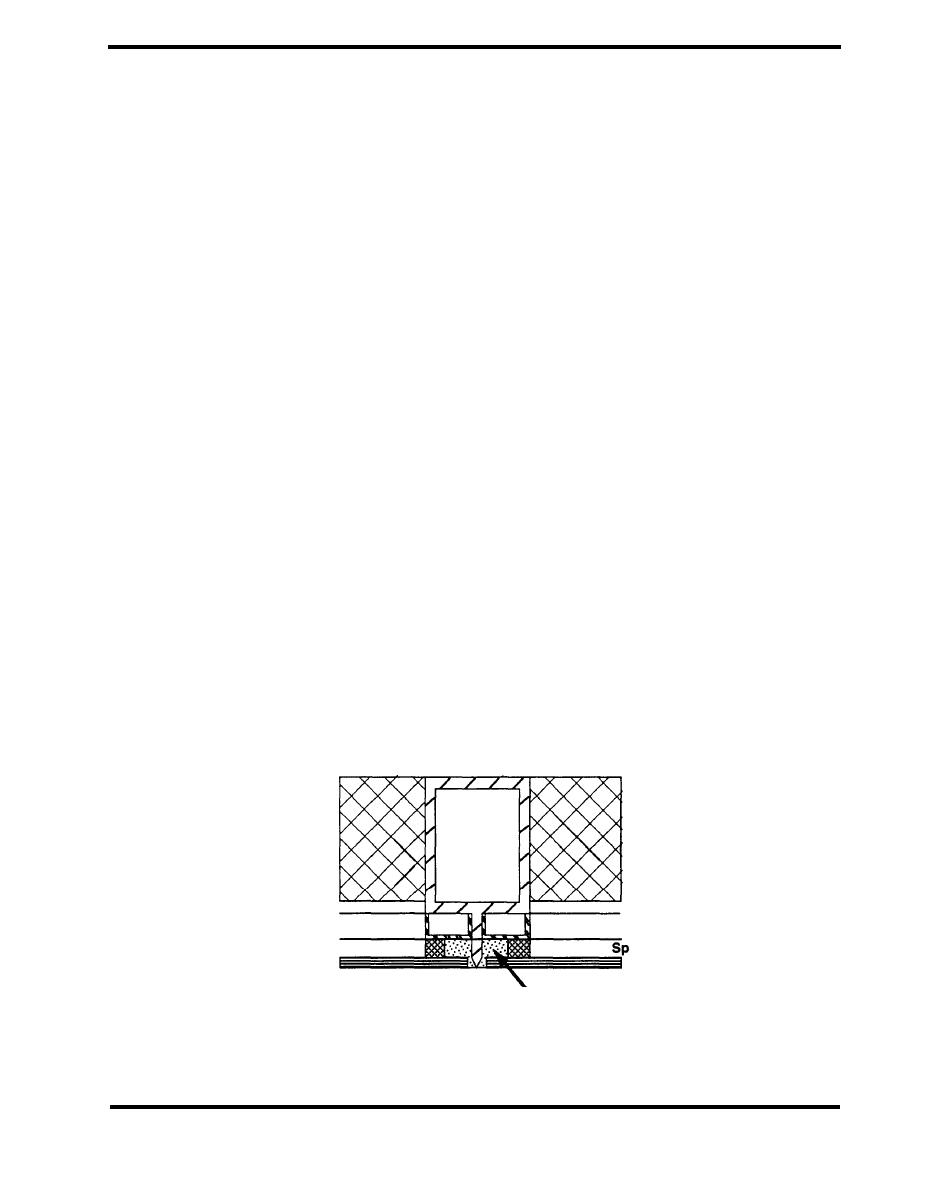

Structural Silicone Glazing

Structural or stopless systems are considered the best design for thermal performance since there

are no exposed mullion surfaces. As shown in Figure 4.1.3, both the vision and spandrel glass are

fixed to the metal support system with structural silicone adhesive sealant. The design of such a

system must insure that there are no exposed metal surfaces that will provide a thermal conduction

path from the exterior to the interior. In heating climates, a vapor retarder is sometimes applied to

the interior of the insulation to prevent condensation in the cavity behind the spandrel glass. For

this vapor retarder to be effective, it must also control air leakage from the building interior into the

space behind the spandrel panel. The application of the structural silicone requires great care with

regard to cleanliness, temperature conditions and curing without stress on the silicone. These

requirements lend this system to the factory assembly of large panels and on-site erection. ASTM

STP 1054 contains several articles on structural silicone glazing systems, though not from the

perspective of thermal performance. These articles cover design considerations, performance

properties of the adhesives, methods for calculating joint dimensions and other issues.

ACCEPTABLE

Insulation

andrel Panel

Structural Silicone

Figure 4.1.3 Structural Silicone Glazing

PAGE 4.1-3

Previous Page

Previous Page