SYSTEMS/MASONRY

When insulation is placed in the cavity, a secure means of attachment is critical. The insulation

within the cavity is subjected to outside wind pressures, and if it becomes displaced, it can interfere

with the drainage of water from the cavity and lose its effectiveness as an insulator. In addition,

there must not be any air gaps behind the insulation, otherwise air will then be able to flow around

the insulation, severely degrading its effectiveness. Rigid insulation boards are often used as cavity

insulation, and in order to be effective, these boards must be fixed tightly to the outside surface of

the backup wall. Depending on the condition of the backup wall surface, it may be necessary to

parge the backup wall to provide a flat surface for application of the insulation. Rigid insulation can

be attached to the backup wall with adhesives, mechanical fasteners or a combination of both.

When using adhesives it is important that the surface of the backup wall is clean and smooth. The

back of the board must be fully buttered with adhesive, since spot adhering will result in air gaps

behind the board. Weather conditions may restrict the use of some adhesives. One must also

address their compatibility with the insulation and their long term stability and effectiveness with

regards to aging, attack from biological organisms, and temperature and humidity cycling.

Mechanical attachment using the brick ties or screw and washer assemblies has advantages over

adhesives since they can be used under any weather conditions. Rigid, fibrous insulation is

sufficiently flexible that mechanical anchors will pull the insulation into close contact with the backup

wall.

When cavity insulation is used, the cavity must be wide enough to allow for the cleaning of any

mortar droppings from the cavity. One can use insulations specifically designed to fill the cavity and

allow for drainage, such as semi-rigid glass fiber boards. Such an approach also has the

advantages of preventing mortar droppings since the insulation is in place when the veneer is

installed.

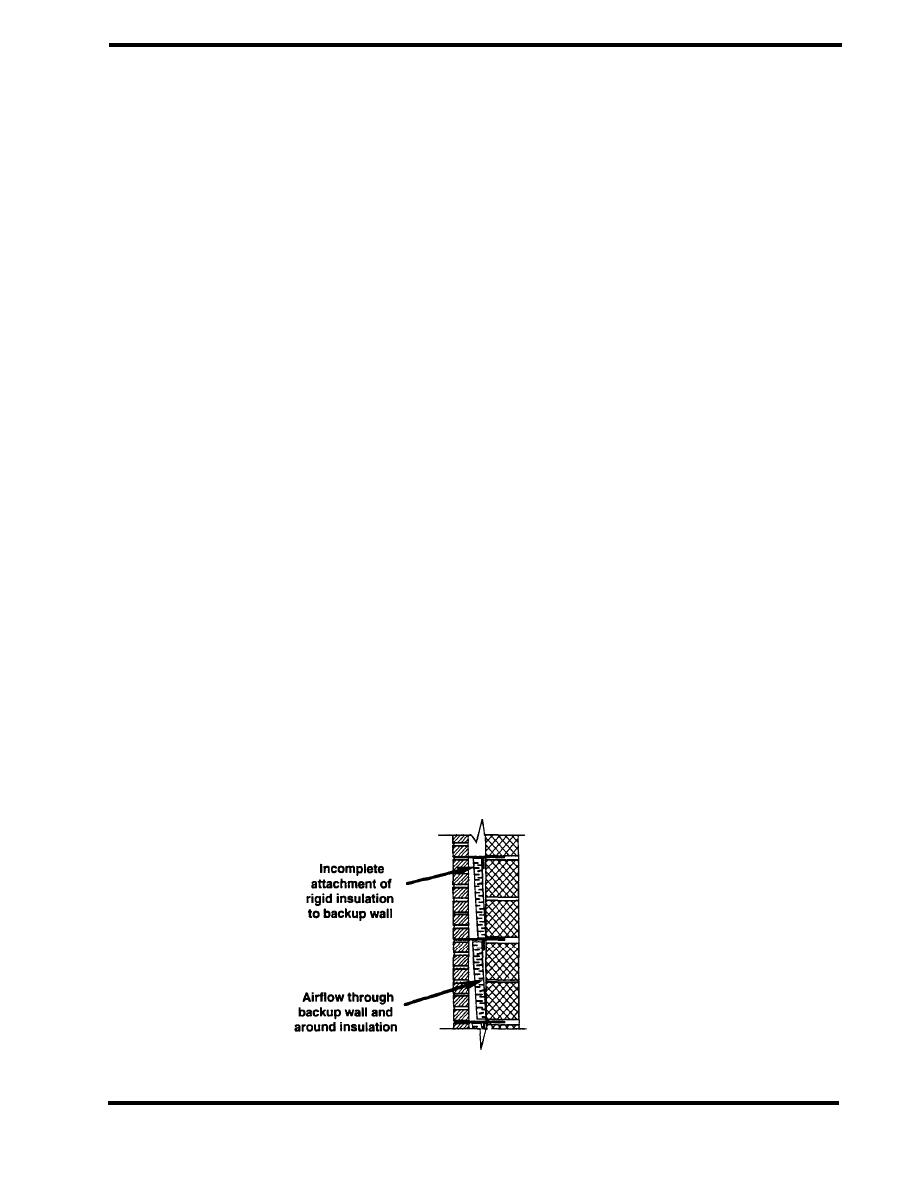

In the case of rigid insulation boards, achieving secure attachment requires a solid surface for

affixing the insulation and a means of attachment that can withstand the environment to which it will

be subjected. Figure 4.2.7 shows an insulation adhesion failure caused when the brick ties

prevented the insulation from achieving full contact with the backup wall. As a result, very little of

the asphalt adhesive on the back on the rigid insulation actually contacted the block. Air moving

through the block wall, due to the lack of an air barrier system, was free to move through the

spaces on both sides of the insulation. In this case, severe condensation resulted on the outer

surface of the backup wall. This problem could have been avoided through the use of an air barrier

system and an alternative means of attaching the insulation.

UNACCEPTABLE

Figure 4.2.7 Insulation Attachment Failure

PAGE 4.2-11

Previous Page

Previous Page