SYSTEMS/MASONRY

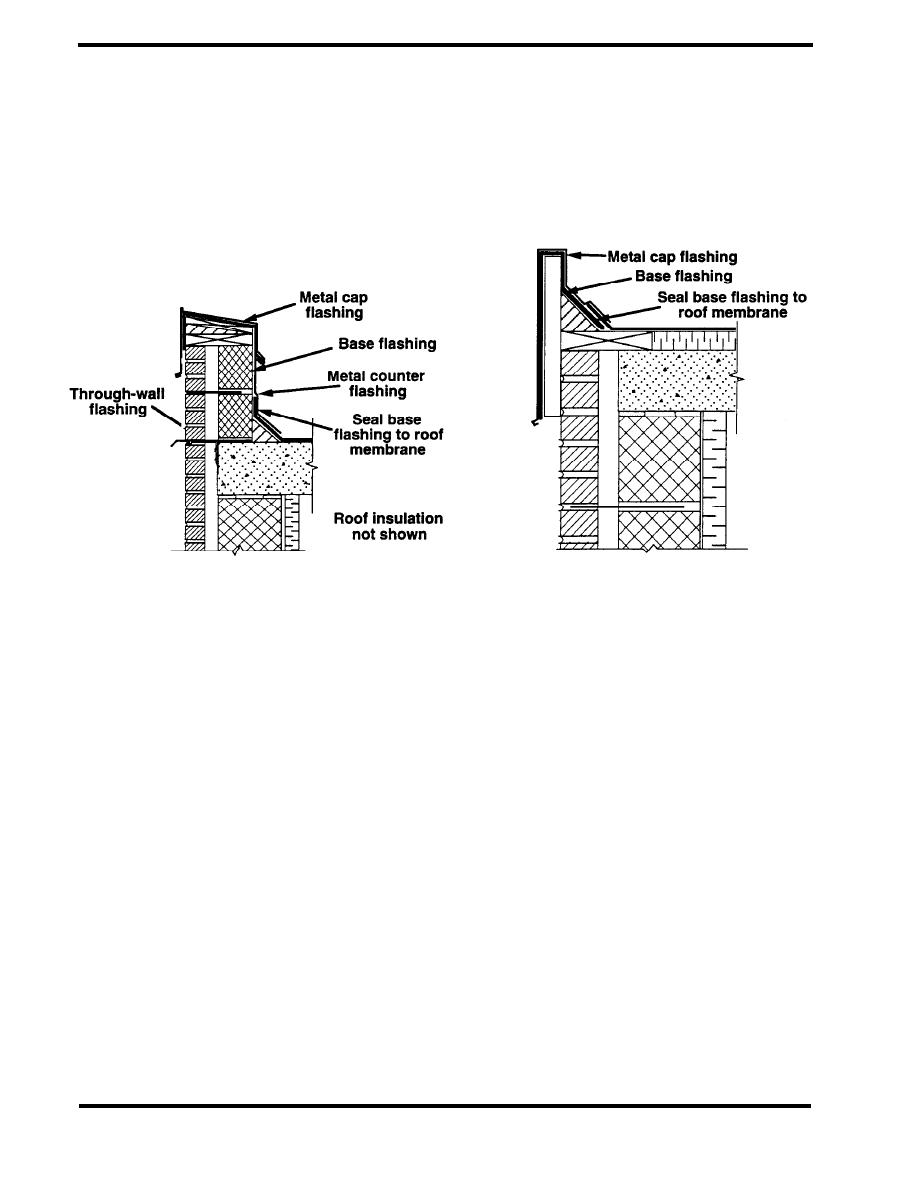

Figure 4.2.5 shows metal cap flashing over the top of a parapet and the through-wall flashing at the

roof line. Figure 4.2.6 shows the flashing at a flashed curb at a roof edge.

ACCEPTABLE

ACCEPTABLE

Figure 4.2.5 Parapet Flashing

Figure 4.2.6 Flashed Curb

(CMHC 1989)

(CMHC 1989)

The consequences of flashing deficiencies are well recognized, and as noted in the CMHC Advisory

Document on Exterior Wall Construction these deficiencies may arise from several causes. First,

flashing may not be called for in the design due to an oversight. In other cases, flashing is included

in the design but is inadvertently omitted during construction. In some designs, the flashing is

carried up a vertical surface to be tucked and sealed into a reglet or notch in the concrete structure

or in a raked-out mortar joint. If this reglet is missing, the flashing may also be omitted or else not

sealed properly, resulting in ineffective performance. Deficient flashing performance also results

when the flashing is damaged during construction by wind or rough handling. A major cause of

poor performance is insufficient flashing details that are oversimplified and neglect interference with

other building elements. For example, flashing may interfere with the shelf angle bolt if the cavity is

too narrow. Detailing problems also occur when flashing intersections with columns and other

contiguous elements are ignored.

PAGE 4.2-8

Previous Page

Previous Page