SYSTEMS/MASONRY

Flashing is required anywhere water might otherwise accumulate or tend to enter the building

interior. These locations include the following: above wall openings such as window heads, below

wall openings such as window sills, where the wall structure rests on the foundation, at shelf

angles, at wall-roof intersections and at parapet copings. A flashing material of good quality must

be specified in the design, based on the following qualities: impervious to moisture penetration,

resistant to corrosion from the atmosphere or caustic substances in mortar, strong enough to resist

puncture, abrasion and other damage during installation, and both easily formed into the desired

shapes and able to retain these shapes in use. Preformed copper sheet flashing, with soldered

joints and expansion provisions, provides good performance. Galvanized sheet steel, aluminum

and lead can be corroded from substances in the mortar and must have protective coatings. The

flashing design must maintain continuity of the flashing at corners and other interfaces, and dams

must be employed where flashing terminates such as beyond window jambs. In order to achieve

the required continuity, flashing installations need to be carefully detailed at all interfaces such as

windows, corners and columns. Adjoining pieces of flashing should be overlapped and properly

sealed to each other. Potential interferences with other envelope elements that might damage or

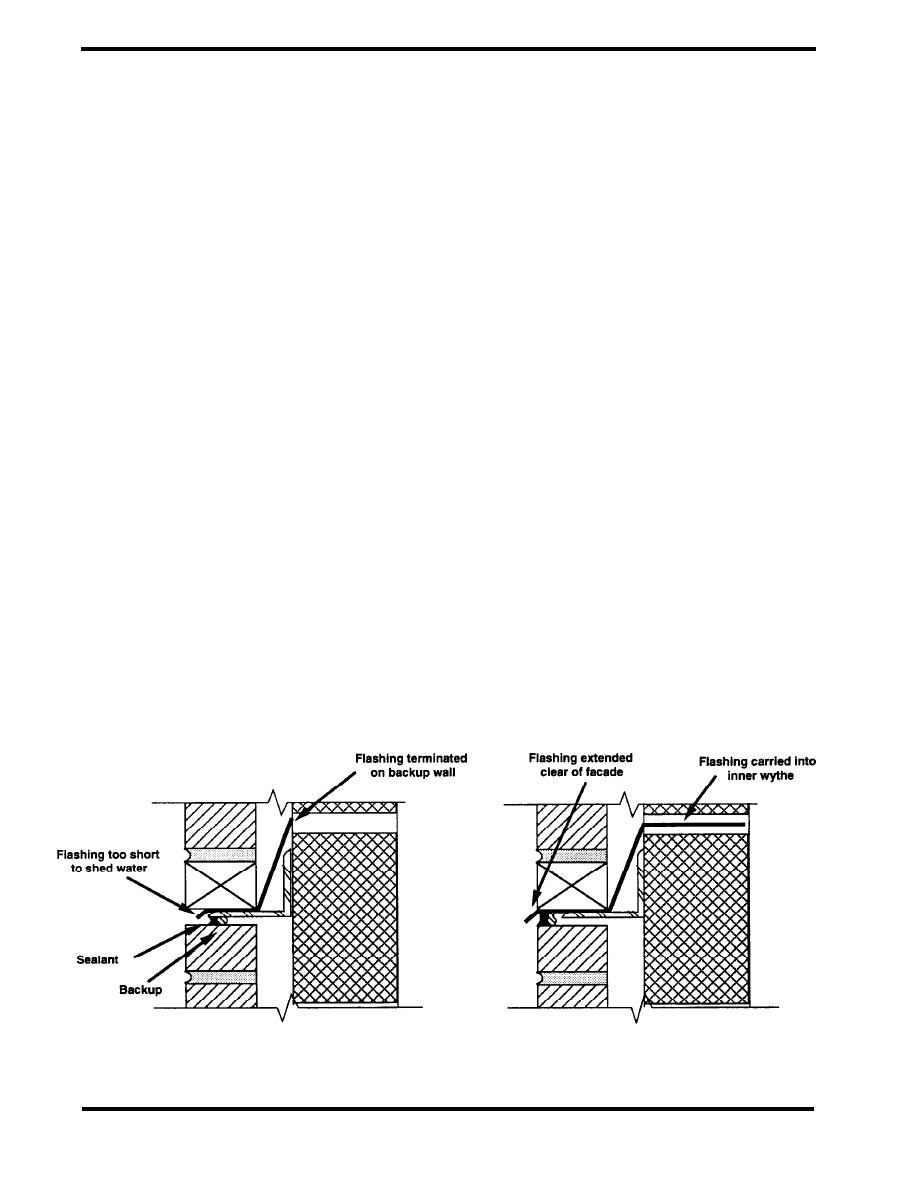

puncture the flashing, such as shelf angle bolts or ties, must be avoided. In cavity walls, the

flashing should be carried up into a mortar joint of the inner wythe. And perhaps most important of

all, the flashing must extend beyond the exterior face of the building. Aesthetic considerations are

sometimes allowed to prevent this essential extension of the flashing, defeating its effectiveness.

Flashing will not be effective unless there are an adequate number of weepholes through which

accumulated water can drain, located immediately above the flashing. Recommendations for the

spacing of weepholes range from 400 to 600 mm (16 to 24 inches) on center. Weepholes can be

provided by leaving mortar head joints open, using removable oiled rods or sashes, or installing

plastic or metal tubes in the head joints. Weepholes can become plugged with mortar during

construction, thereby losing their ability to drain. Construction techniques exist to prevent this

problem, and these are described below in the section on Construction Requirements. Other

weephole deficiencies include their complete omission or inadequate spacing or number.

UNACCEPTABLE

ACCEPTABLE

Figure 4.2.3 Unacceptable and Acceptable Flashing and Sealant Details (CMHC 1989)

PAGE 4.2-6

Previous Page

Previous Page