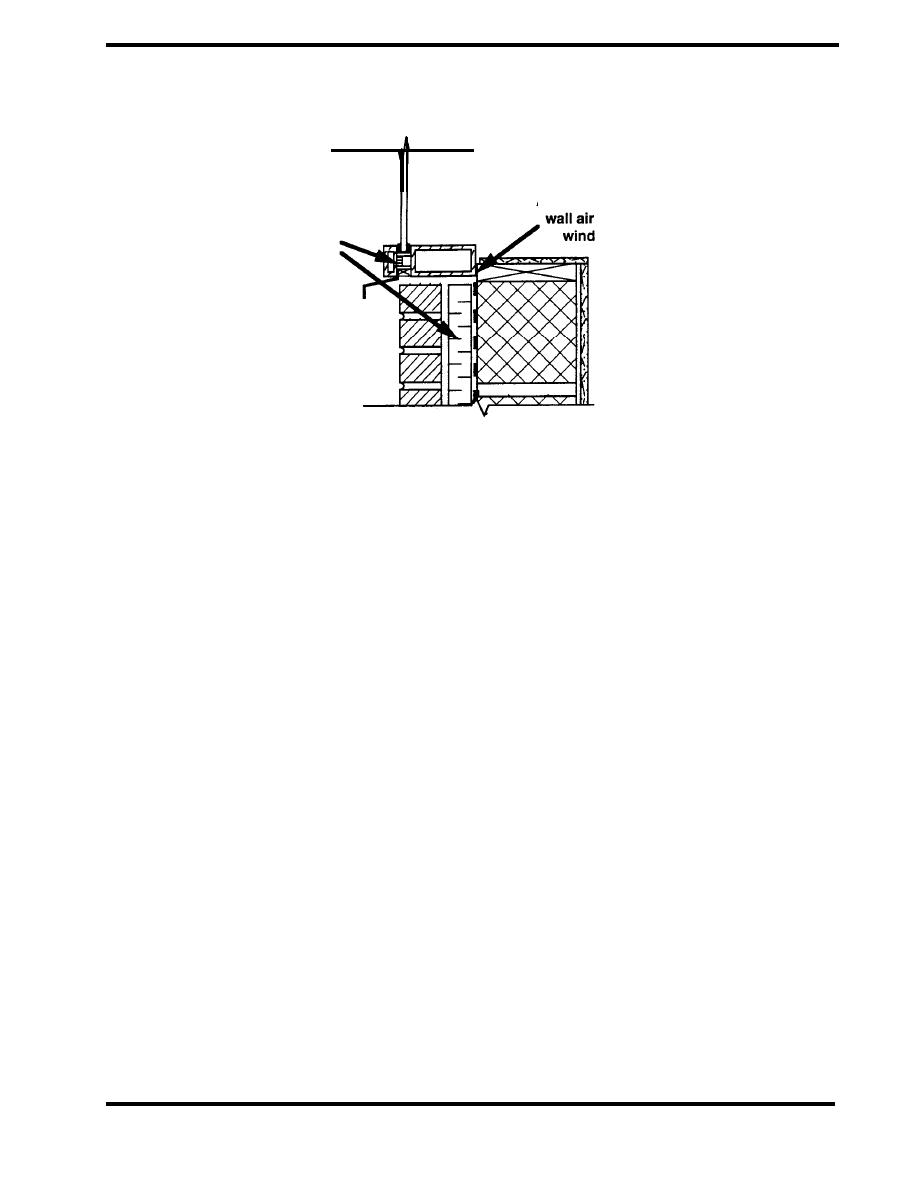

SYSTEMS/MASONRY

UNACCEPTABLE

Air leakage between

Wall insulation out

barrier and

of line with mullion

ow frame

thermal break

Figure 4.2.11 Air Leakage at Window/Wall Interface

(Quirouette 1983)

Vapor retarder design for masonry walls must follow the guidance in the section Design/Vapor

Retarders. The vapor retarder need not be absolutely continuous like the air barrier, but it must be

applied to all portions of the envelope. Areas that are sometimes neglected include walls above

suspended ceilings and behind convector cabinets. The position of the vapor retarder within the

wall depends on the climate and the placement of the thermal insulation, and needs to be

considered on a case by case basis as described in the section Design/Vapor Retarder. In some

designs the air barrier is also intended to act as the vapor retarder, and in these cases the same

analysis of vapor transport needs to be conducted.

There are several different options for providing a vapor retarder in terms of location and materials.

The CMHC Seminar on brick veneer wall systems describes options for heating climates. First, the

vapor retarder can be part of the interior finish, a necessity when the insulation is placed inside of

the backup wall. Appropriate materials include oil or alkyd paint over gypsum board, polyethylene

over the insulation, and impermeable insulation itself. If the insulation is positioned in the cavity, the

vapor retarder can be located on the inside face of the backup wall using paint or other vapor

retarding materials. A membrane on the exterior face of the backup wall can also serve as a

combination vapor retarder and air barrier. Self-adhesive and torched-on membrane materials are

effective. Since the membrane is serving as an air barrier, it must be continuous, able to

accommodate movement cracks and remain firmly attached over time despite air and vapor

pressures. When rigid insulation is applied to the external face of the backup wall, the mastic

adhesive will serve as a vapor retarder. To be effective, a full bed of mastic must be applied and

joints between insulation boards must be fully buttered.

PAGE 4.2-15

Previous Page

Previous Page