DESIGN/SEALANTS

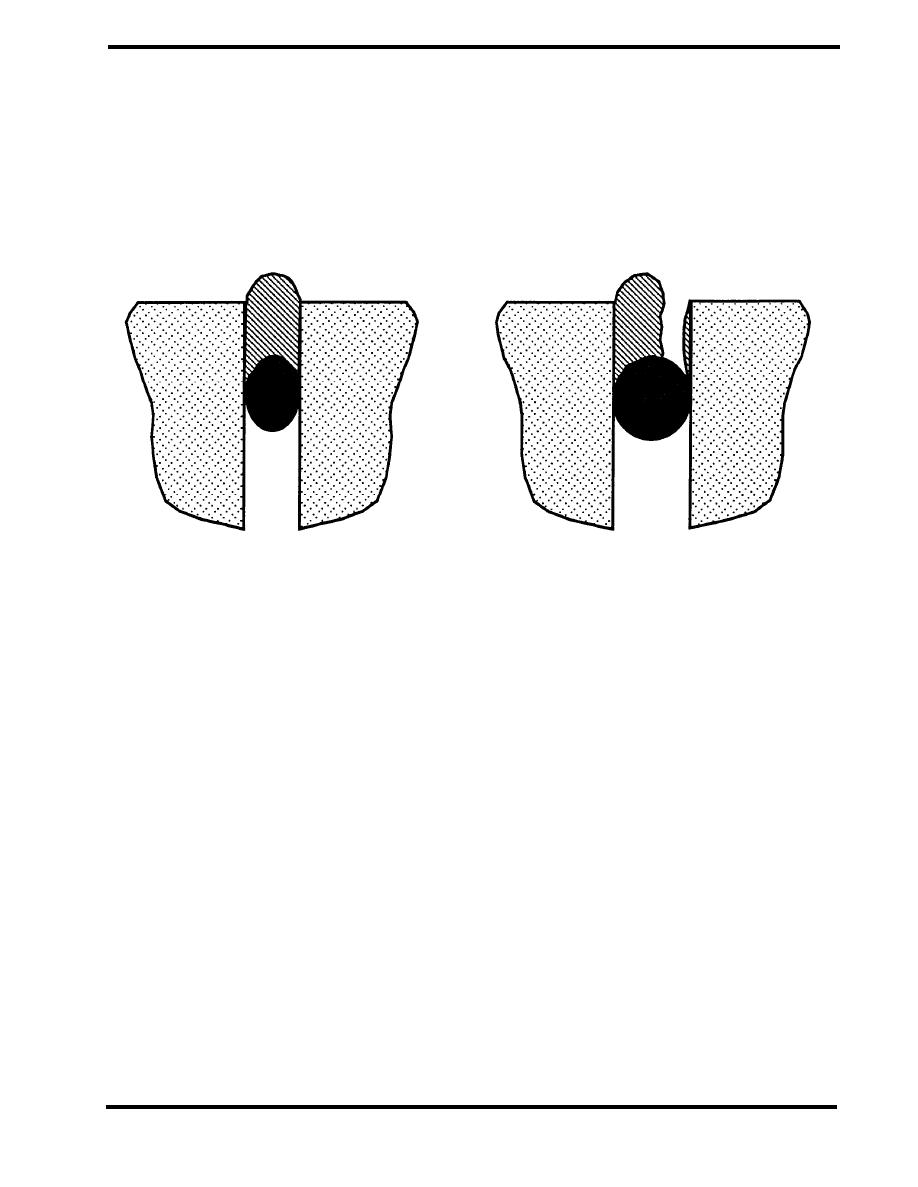

Other sealants remain bulged after compression and will not restretch, so-called compression set,

as shown in Figure 3.5.5. in this situation, the joint sealant will fail cohesively when the joint

reopens.

UNACCEPTABLE

Joint under expansion

Joint under compression

Figure 3.5.5 Compression Set Sealant (Warseck)

Backup Materials

The selection and sizing of backup materials, often a backer rod, is another crucial aspect of

sealant joint design. General discussions of sealant backup materials are presented by Balliet and

Panek in ASTM STP 606 and by Schroeder and Hovis in ASTM STP 1069. The purpose of a

sealant backup is to limit the depth of the sealant bead, to enable the proper shaping to the sealant

by providing support to tool against, and to act as a bondbreaker to prevent back-side adhesion of

the sealant. In order to provide adequate performance, backup materials must not absorb water,

must not offgas and cause bubbling within the sealant, must remain flexible at low temperatures,

and must be compatible with the sealant material. Because it may be many months between the

installation of the backup and the sealant application, the backup material must be able to perform

as a temporary seal during this period of time. Closed-cell backer rods are a common backup

material, though offgassing can be a problem with the slow-curing sealants in use today. If the

backer rod is punctured or somehow damaged during installation, the gas emitted from these

ruptured cells can be pumped into the uncured sealant by thermally-induced cycling of the backup.

Gas bubbles in the sealant can degrade the cohesiveness of the sealant and lead to performance

problems. New developments of backup materials that do not offgas when ruptured are described

by Schroeder and Hovis in ASTM STP 1069. In addition to proper backup material selection, the

sizing of the backer rod relative to the joint width is important. The backer rod should be sized such

that it is held in place by compression in its final position and remains in place through the

dimensional changes in the joint width. Warseck recommends that the backer rod be sized about

30% greater than the maximum expected joint opening.

PAGE 3.5-9

Previous Page

Previous Page