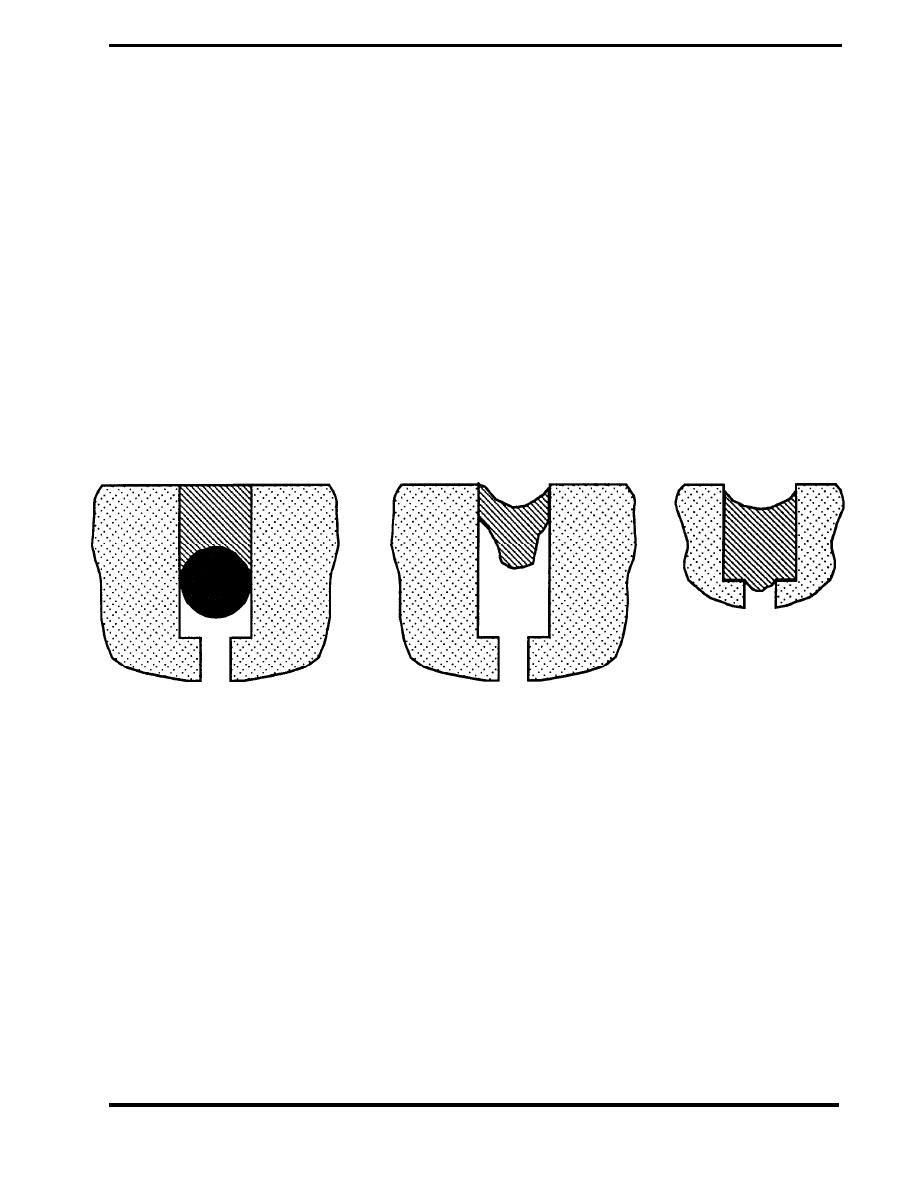

DESIGN/SEALANTS

Figure 3.5.3 shows three examples of poor joint design. In the first case the sealant is not tooled to

the proper depth, the sealant bead is too thick and the bead width-to-depth ratio is too low. In the

second example, there is no backer rod, no support to tool the sealant against, and the bead is too

thick. In the third case there is no backer rod so the sealant is bonding against the back of the joint,

resulting in so-called three-sided adhesion. This will result in cohesive and/or adhesive failure of

the sealant.

The location of the sealant joint within the wall is an important design and installation consideration.

Locating the sealant joint at the exterior subjects the sealant to the most extreme environmental

conditions and the largest differential movements. If the sealant joint is located inward, it is

protected from most of the environmental extremes and is subjected to smaller differential

movements. Also, interior sealants can be installed from inside the building simultaneously with

erection of panels on upper floors and under more severe weather conditions than exterior sealant

application. The application of an interior sealant can be complicated by the location of columns,

beams and floor edges, and these interferences must not be overlooked in the design phase.

UNACCEPTABLE

Sealant not tooled properly

No backer rod

No backer rod

Sealant bead too thick

Sealant bead too thick

Sealant bonding to back of joint

Wrong width-to-depth ratio

No support to tool against

Joint cut too shallow

Figure 3.5.3 Poor Joint Designs (Schroeder and Hovis)

Most guidance on the design and installation of sealant joints contained here and elsewhere

concerns simple horizontal and vertical joints and does not generally address more complex joint

configurations. These include intersections of horizontal and vertical joints, doglegs and other

transitions. The lack of adequate design details for these complexities are a common source of

performance problems due to the unusual stresses and movements that occur at these locations.

An adequate joint design must include details for all joints, intersections between joints and

locations where joints terminate at other envelope components. Without the provision of design

details at all locations, the sealant installation at irregular joints is left to the mechanic in the field.

PAGE 3.5-7

Previous Page

Previous Page