DESIGN/SEALANTS

Sealant Materials

The primary criteria for the selection of a sealant material is the ability to accommodate the

anticipated movement under the expected environmental conditions and to maintain an adequate

level of performance over time. Sealants at exterior joints are subjected to environmental factors

that can accelerate their deterioration: extreme temperatures, solar and ultraviolet radiation, large

differential movements, frequent wetting, and physical abuse. Other performance factors include

adhesive and cohesive properties, weather resistance and durability, workability at different

temperatures, compatibility with the substrate and puncture resistance. Panek presents a brief and

up-to-date discussion of sealants materials and their properties. ASTM STP 606, published in

1976, also contains a thorough discussion of many different sealant materials.

Warseck points out that the most common sealant design failure is the selection of a sealant with

insufficient movement capability, pointing out that sealant "performance" is not a well-defined

quantity. This leads to confusion when selecting and comparing sealants. Other sealant selection

problems are due to incompatibility of sealants with materials in close proximity including

substrates, primers and other sealants.

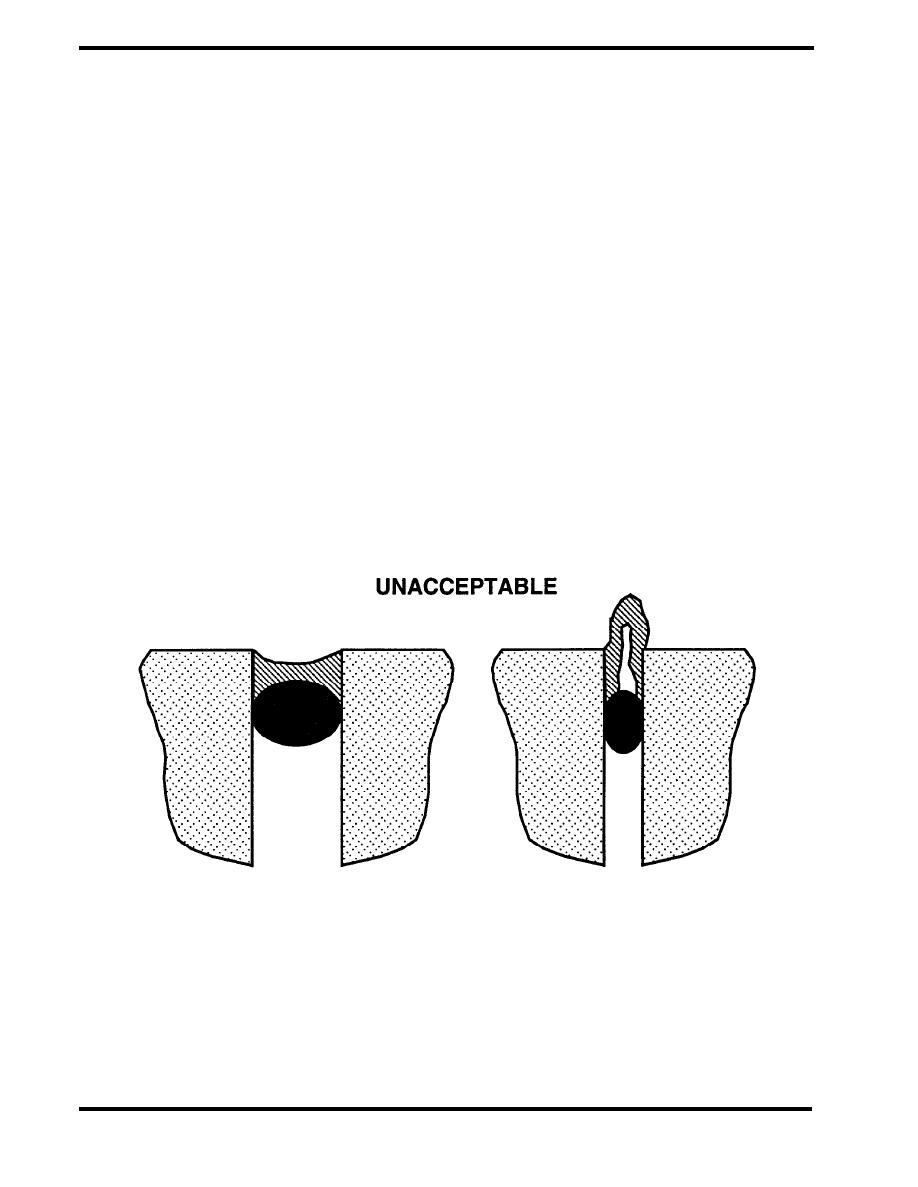

Another point raised by Warseck is the use of sealants with insufficient recovery. A sealant with

poor recovery may stretch adequately, but will not easily return to its original shape, so-called stress

relaxation. As shown in Figure 3.5.4, the sealant bead assumes a distorted shape, and when the

joint reopens the sealant will fail.

Joint under compression

Joint under expansion

Figure 3.5.4 Stress Relaxed Sealant (Warseck)

PAGE 3.5-8

Previous Page

Previous Page