DESIGN/RAIN PENETRATION

There are essentially three approaches to water leakage control: face-seal, two-stage seal and the

pressure-equalized rain screen. The first two approaches attempt to the seal the facade to rain

penetration and air leakage, while the third approach attempts to control the forces of rain

penetration including the elimination of air pressure differences across the joint.

The face seal approach employs a single line of defense against rain penetration and air leakage by

employing a field-installed elastomeric joint sealant (see section Design/Sealants). A simple one-

stage joint is shown in Figure 3.4.1. This is the lowest initial cost option and can perform well for

several years, given good joint design, good sealant materials, careful installation and nominal joint

width and movement. However, as mentioned above, the sealant is fully exposed to the degrading

effects of sunlight, ultraviolet radiation, water and temperature cycling, increasing the material

requirements on the sealant material. Over time the performance of these sealants will decrease,

increasing maintenance costs. Also, any defect in the sealant, even a small gap in the sealant

adhesion, will lead to both water and air leakage.

Air and water seal

Figure 3.4.1 Section of Vertical, One-Stage Joint

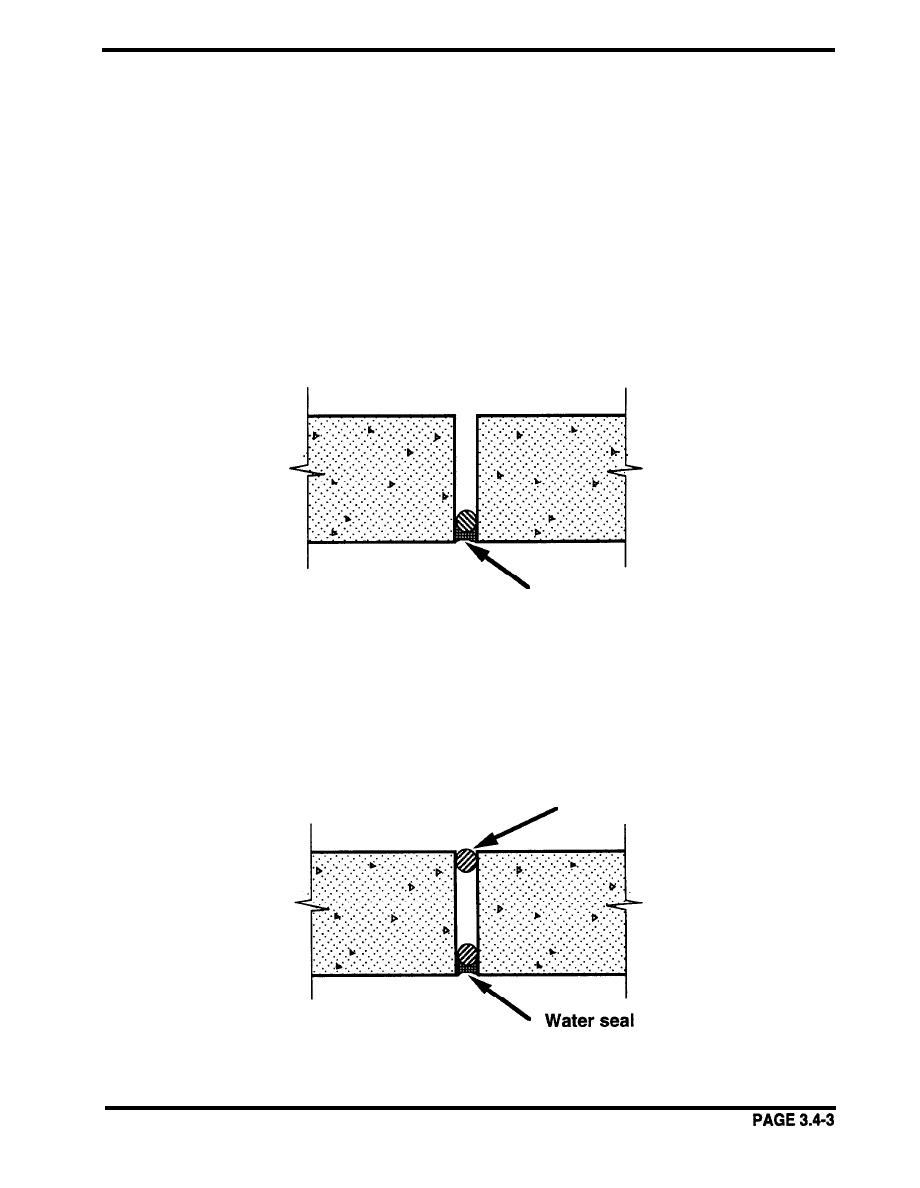

Two-stage joints employ an outer seal to control water leakage and an inner seal for air-tightness, as

shown in Figure 3.4.2. These joints are sloped downward to prevent gravity-driven flows into the

joint and are wide enough to reduce capillary action. The outer rain seal serves to control kinetic

energy. Any rainwater that does penetrate the rain barrier drains to the outside, well before it is

able to reach the air seal. The inner air seal is now in a less severe environment, being protected

from water and ultraviolet radiation, placing less severe requirements on the sealant material.

Air seal

Figure 3.4.2 Section of Vertical, Two-Stage Joint

Previous Page

Previous Page