SYSTEMS/PRECAST

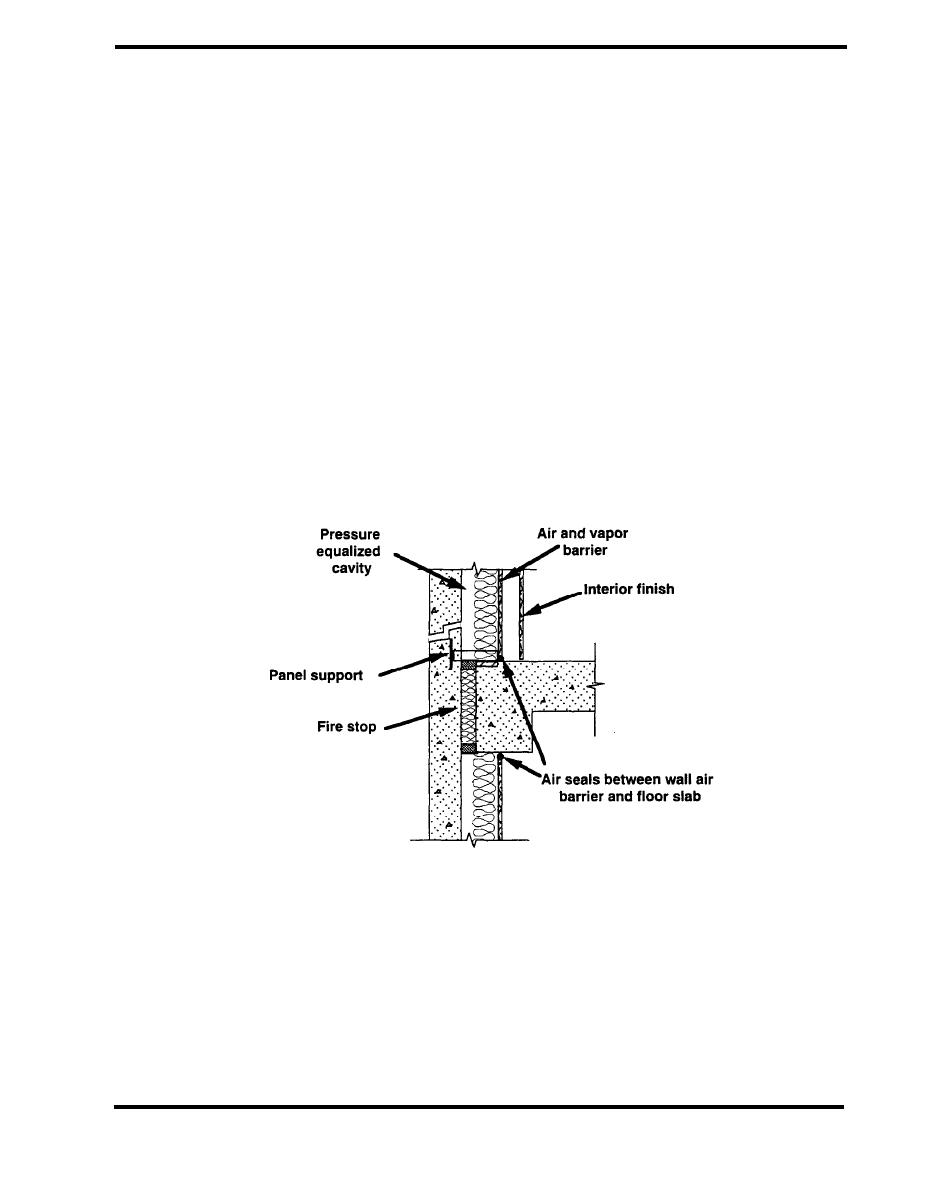

A pressure-equalized rain screen design approach, discussed in the section on Water Leakage and

Joint Design, solves many of these problems in heating climates if designed and installed properly.

This approach to precast wall construction has been discussed as early as 1967 by Latta. In this

approach, the air barrier is installed behind the insulation, where it is protected from fluctuations in

outdoor temperatures. Figure 4.4.8 shows a sketch of a precast panel wall employing a pressure-

equalized rain screen from Rousseau. In this particular example, a layer of gypsum board on the

inside of an insulated steel stud wall serves as the air barrier. Air seals are used where this

gypsum meets the floor slab to maintain the continuity of the air barrier system. A vapor retarder is

also installed outside of the gypsum board. A second layer of gypsum is located inside of the air

barrier to create a cavity for the installation of services to avoid compromising the air barrier. A

pressure equalized cavity exists between the insulation and the precast cladding. The pressure

equalization is achieved through the open horizontal joints, which are sloped to the outside for

drainage. There is no need for any sealant at these joints if they are properly designed to deflect

and shed water. The cavity must be properly flashed from the cladding to the inner air barrier.

ACCEPTABLE

Figure 4.4.8 Pressure Equalized Rain Screen (Rousseau)

PAGE 4.4-9

Previous Page

Previous Page