SYSTEMS/PRECAST

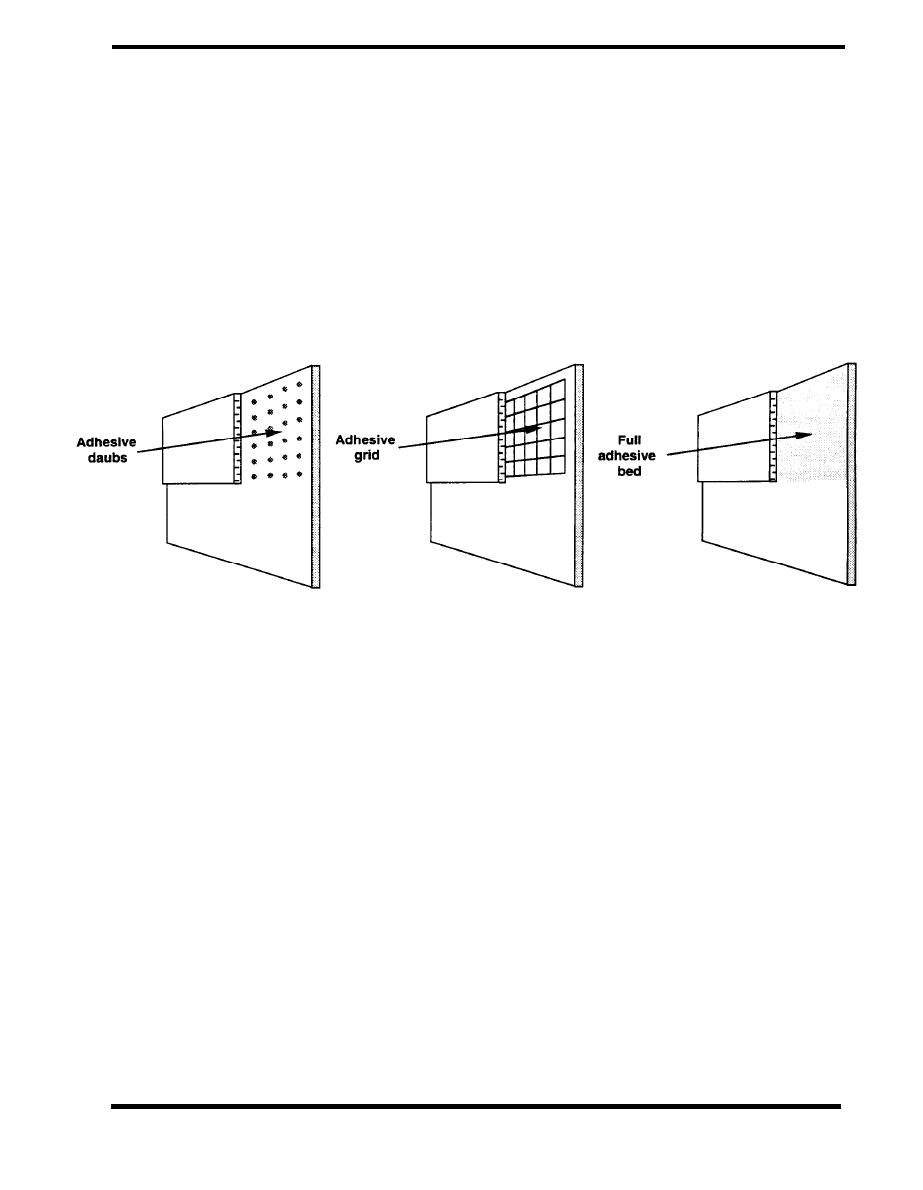

Rigid insulation can be installed on the back of precast panels using adhesives or a variety of

mechanical attachment systems. If an adhesive is used, it must be compatible with the insulation

material. The adhesive should not be applied in daubs as shown in Figure 4.4.7, from Architectural

Precast Concrete (PCI). Using daubs of adhesive creates air gaps behind the insulation, which in

turn lead to airflow behind and around the insulation. Besides decreasing the thermal effectiveness

of the insulation, such airflows can also lead to condensation on the back of the panel. A grid of

adhesive beads is an improved method of application, while a full bed of adhesive provides the best

performance. A full bed will act as a vapor retarder, and its water vapor permeance must be

analyzed with reference to the entire wall system. If a vapor retarder is unacceptable at this

location, a grid of adhesive may be used instead.

BETTER METHOD

RECOMMENDED

NOT RECOMMENDED

Figure 4.4.7 Application of Rigid Insulation with Adhesives (PCI)

A variety of mechanical means exist for attaching insulation onto panels including stick clips and

furring systems. In all cases, it is important that the insulation is attached tightly to the precast

concrete with no air spaces between the two elements. Such air spaces will decrease the

insulation performance. Rigid fibrous insulation boards have been recommended because they are

sufficiently flexible to conform to irregularities in precast panel surfaces.

Precast concrete sandwich panels incorporate the thermal insulation within the concrete panel,

between two wythes of concrete. The interior finish system can also be incorporated directly onto

the factory-made panel. As discussed in Architectural Precast Concrete (PCI) and in Sauter, this

approach can improve the thermal performance of the wall by enabling good insulation system

continuity. In order to achieve this continuity in a sandwich panel, the use of concrete webbing and

framing within the panel must be reduced. Further improvements can be obtained by using

nonconductive ties between the two wythes of concrete, e.g. composite materials. The references

contain a great deal of information on sandwich panel walls, including their attachment and the

design of ties. The performance of the whole wall system is determined in large part by the design

and performance of the panel joints in terms of water and airtightness. These joints must be

designed in conjunction with the panels and the air barrier system. Sauter contains a series of

precast sandwich panel details that show how insulation system continuity is maintained with this

system. However, these details do not explicitly address air leakage control.

PAGE 4.4-7

Previous Page

Previous Page