DESIGN/AIR

BARRIERS

Structural Integrity: All elements of the air barrier must be able to resist the imposed pressure

loads or be supported by something that can resist these pressures. If the air pressure difference

across the building envelope is not able to move air, it will work to displace those materials that are

preventing this airflow. If the pressure exceeds the capability of the air barrier system to support

this pressure load, then the system will fail, permanently destroying its ability to provide air-tightness.

In more specific terms, the air barrier system must resist peak wind loads, stack pressures and

(de)pressurization by ventilation equipment without rupturing or detaching from its support and must

not creep away from its supports or split at joints under sustained air pressures.

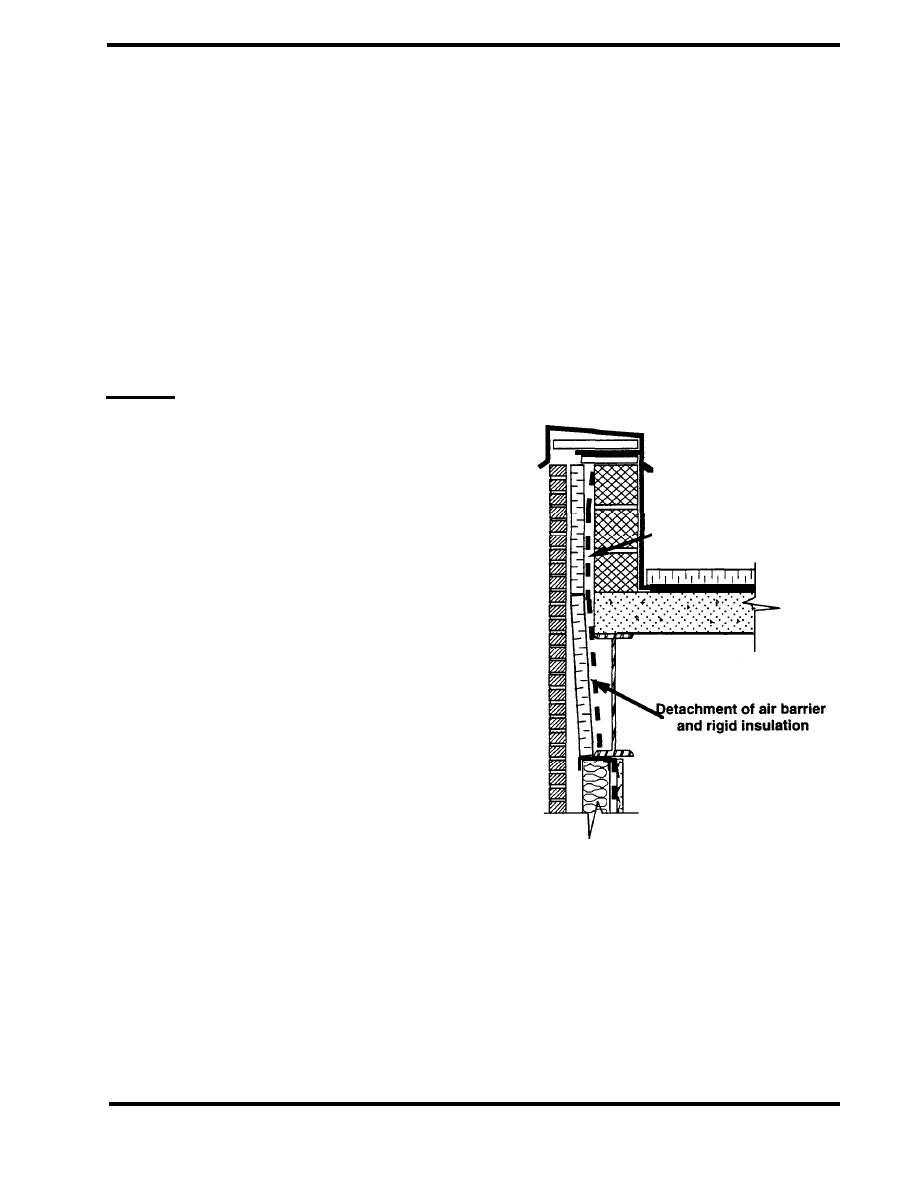

Example: A case of inadequate structural

UNACCEPTABLE

support of the air barrier in a parapet wall is

shown in Figure 3.1.2 (Quirouette 1989). The

wall consists of a brick veneer, an insulated steel

stud wall, a polyethylene sheet air barrier/vapor

retarder and an interior drywall finish. The

parapet consists of a brick veneer, rigid

insulation, polyethylene and concrete block

Air Barrier

backup. The rigid board parapet insulation was

spot adhered to the polyethylene, which ran from

the top of the wall studs, past the steel beam,

and up the parapet where it was sealed to the

parapet top plate. Because the polyethylene

was not adequately supported, it moved back

and forth with the wind pressures and eventually

tore. The movement of the polyethylene pulled

the rigid insulation from its original location,

which in turn pulled the polyethylene further out

of place. The parapet air seal was rendered

totally ineffective, and the effectiveness of the

insulation was severely degraded.

Figure 3.1.2 Failure of Air Barrier

Integrity (Quirouette 1989)

PAGE 3.1-3

Previous Page

Previous Page