DESIGN/AIR

BARRIERS

Material and System Requirements

There are four basic requirements for an effective air barrier system: continuity, structural integrity,

air-tightness and durability.

Continuity: Continuity throughout the entire building envelope is one of the most important

requirements of the air barrier system. It means much more than the various elements not having

holes; continuity requires that all of the air barrier components are sealed together so there are no

gaps in the envelope airtightness. The sealing of component connections is essential to air barrier

design and construction, and a common source of failures. Areas where air barrier continuity must

be given particular attention are at window frames, utility penetrations, wall-roof connections and

the intersections of different wall systems.

The air barrier in each envelope component must be clearly identified during the design, and the

manner in which they will be sealed together at component connections must be well thought out.

Air barrier continuity can also be violated at locations that are hidden by other envelope

components. For example when the interior finishing (e.g. gypsum) serves as the air barrier, if it is

sometimes not finished above suspended ceilings or behind convector cabinets, there will be large

gaps in the air barrier system's continuity.

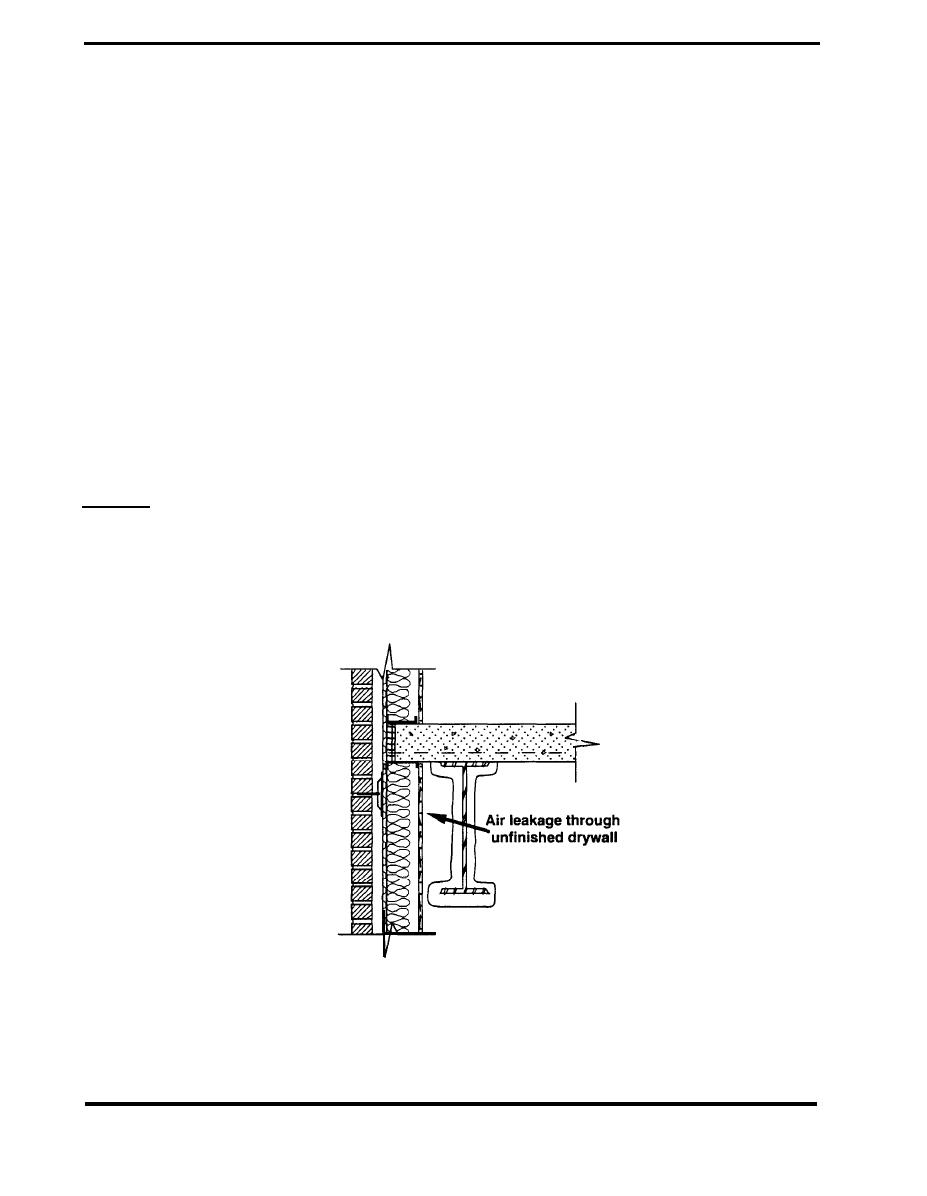

Example; The sketch in Figure 3.1.l shows a failure in air barrier continuity due to a lack of interior

finishing (Kudder). In this wall the interior drywall served as the air barrier. However, due to the

obstruction of the spandrel beam, the drywall could not be finished and severe air leakage occurred

around the beam into the cavity behind the facade. Drywall screws were not installed behind the

beam, and the joints were not taped all the way up the height of the wall.

UNACCEPTABLE

Figure 3.1.l

Failure of Air Barrier Continuity (Kudder)

PAGE 3.1-2

Previous Page

Previous Page