probability no higher than 750 breaks per 1000 when

glazing attached by structural silicone or with anchored

calculating loads to frames and anchorage.

security films.

While most test data use glazing framed with a deep bite,

All glazing hazard reduction products for these protection

this may not be amenable to effective glazing performance

levels require product-specific test results and engineering

or installation. It has been demonstrated that new glazing

analyses performed by qualified independent agents

systems with a 3/4-inch minimum bite can be engineered

demonstrating the performance of the product under the

to meet the performance standards of Table 8-2 with the

specified blast loads, and stating that it meets or exceeds

application of structural silicone. However, not much

the minimum performance required. Performance levels

information is available on the long-term performance of

are based on the protection conditions presented in Table

8-2. A Government-provided database indicating the

performance of a wide variety of products will be made

available to the designer.

Table 8-2

Window Fenestration: The total fenestration openings

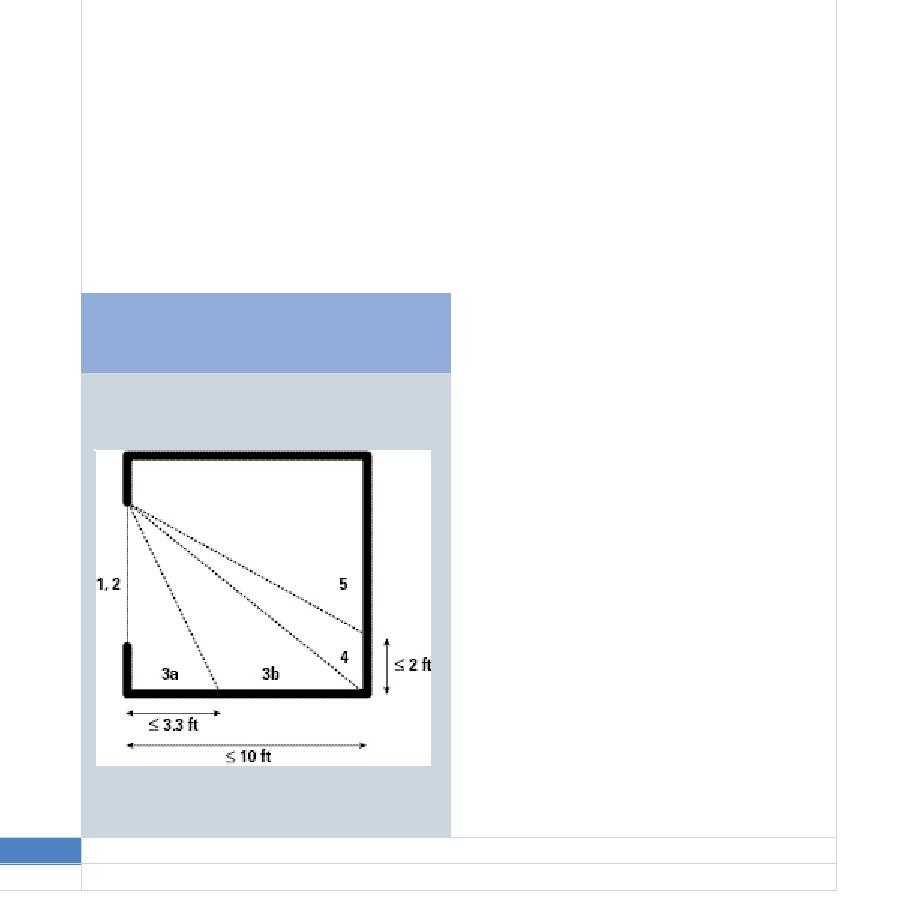

Test Structure

are not limited; however, a maximum of 40 percent per

structural bay is a preferred design goal.

Window Frames: The frame system should develop the

Side view of test structure illustrating

full capacity of the chosen glazing up to 750 breaks per

performance conditions of Table 8-1

1000, and provide the required level of protection without

failure. This can be shown through design calculations or

approved testing methods.

Anchorage: The anchorage should remain attached to the

walls of the facility during an explosive event without

failure. Capacity of the anchorage system can be shown

through design calculations or approved tests that

demonstrate that failure of the proposed anchorage will not

occur and that the required performance level is provided.

Glazing alternatives. Glazing alternatives are as follows:

Preferred systems include: thermally tempered glass with

a security film installed on the interior surface and

attached to the frame; laminated thermally tempered,

laminated heat strengthened, or laminated annealed glass;

and blast curtains.

Acceptable systems include monolithic thermally tempered

glass with or without film if the pane is designed to with-

stand the full design threat (see Condition 1 on Table 8-2).

Test window should be in the design

position or centered on the wall.

246 F A C I L I T I E S S T A N D A R D S

FOR THE

PUBLIC

BUILDINGS

SERVICE

8.4 New Construction

Revised March 2005 PBS-P100

Previous Page

Previous Page