SYSTEMS/PRECAST

4.4 PRECAST CONCRETE PANELS

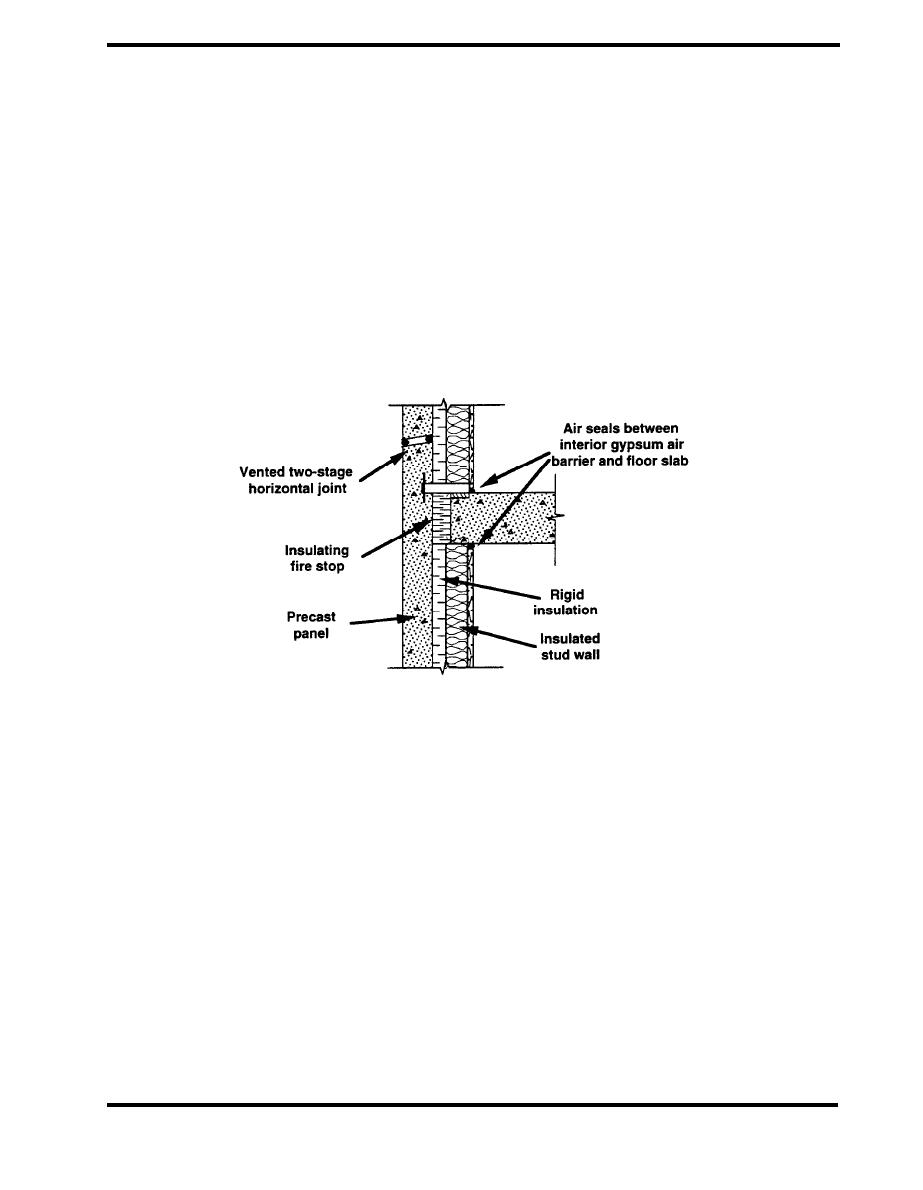

Precast concrete panel walls are composed of factory-made concrete panels erected on a structural

frame of steel or cast-in-place concrete. Additional elements are installed inside of, and perhaps

within, the panels to fulfill other building envelope requirements. Figure 4.4.1 shows the basic

elements of a precast concrete panel wall. In so-called conventional systems, the panels constitute

a single-wythe facade and the inner wall contains thermal insulation, an air barrier, a vapor retarder

and other elements. In precast sandwich panel walls, the precast unit contains the insulation, vapor

retarder and air barrier. The sandwich panels are then erected on the structural frame, the panel

joints are sealed, and the interior finish is applied. Precast concrete panel walls can be either load-

bearing or nonload-bearing.

ACCEPTABLE

Figure 4.4.1 Precast Panel Wall (PCI)

Precast concrete panel walls offer several advantages including great flexibility of form, color and

texture. The functional advantages of precast concrete include good crack control, fire resistance,

durability, low maintenance, and airtightness of the panels themselves. The on-site erection of

these units is also relatively fast and less influenced by weather conditions than other systems.

These advantages, along with the basics of precast panel wall design, are discussed in the PCI

Design Handbook, Architectural Precast Concrete also published by PCI, and Freedman.

As with other walls systems, the key to achieving good thermal and airtightness performance in

precast concrete panel walls is maintaining the continuity of the thermal insulation and air barrier

systems. Other related performance issues in precast systems include the control of water

leakage, weathering and condensation. Because the panels themselves are airtight and watertight,

many aspects of their thermal performance are determined by the joints between the panels rather

than by the panels themselves. Rain penetration can be a problem at the panel joints and at

window penetrations. Air leakage through panel joints can lead to condensation within the wall,

increasing the potential for corrosion of metal panel supports. Thermal bridges occur both at panel

joints and at the panel supports.

PAGE 4.4-l

Previous Page

Previous Page